Custom Metal Fabrication

We Know Metals

Your Full Service Fabrication Shop

We offer comprehensive fabrication services to a wide variety of folks. Our fabrication capabilities include – but are not limited to – a variety of ferrous (steel & stainless) and non-ferrous welding applications (copper, brass, bronze, aluminum), proprietary patinas and finishes, milling and turning, assembly, sheet metal fabrication, bending and forming, CNC cutting, and just about any custom fab application you can envision. EA also provides a full range of design and prototyping capabilities.

A Full-Service Fabrication Shop

Welding

When talking about welding, we know our stuff. We are set up for MIG (metal inert gas) and TIG (tungsten inert gas) as well as oxy-fuel (oxyacetylene welding, brazing) and spot (electric resistance) welding.

- MIG – uses a metal wire fed through the machine like a hot glue gun for quick and reliable welds

- TIG – a more precise and cleaner method compared to MIG that leaves a beautiful weld that can be left as a decorative feature

- Oxy-fuel – like soldering jewelry, this uses a controlled torch flame. This is the oldest type of welding, and now we use it for brass.

- Spot Welding – used for a quick and efficient way to join sheet metal by melting the metal together

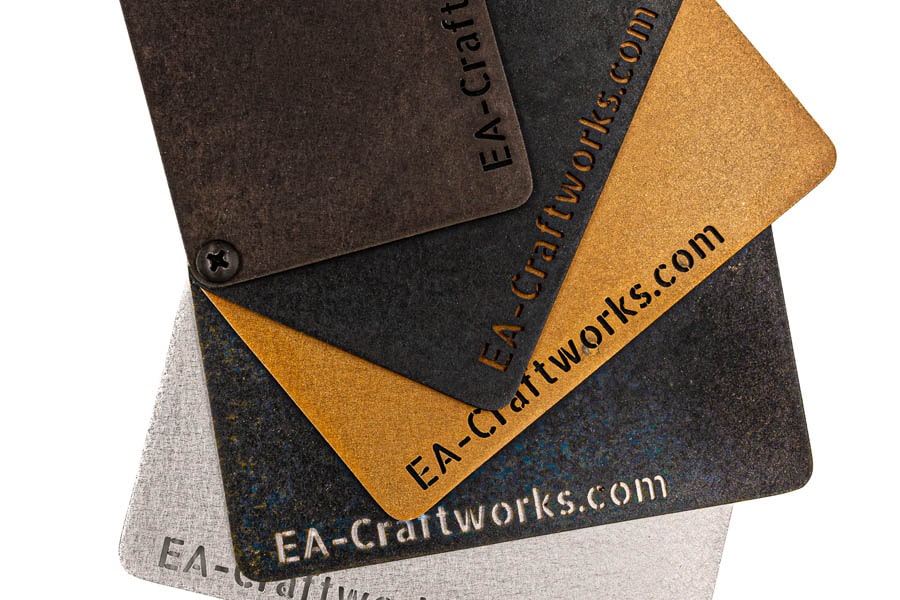

Metal Finishes

Our finishing services include custom etching, polishing, a variety of patina options, and we work with great powder coat partners. We offer custom metal finishing to bring polish, character, and quality to your project. We meet any design need, from raw steel rusting to etching raw brass, copper, bronze, aluminum, and steel. Our finishes go beyond aesthetics and can also provide environmental protection for long lasting endurance.

Milling, Turning, Bending & Forming

We have the capacity to mill and turn a broad variety of materials. Steel, Stainless Steel, Brass, Bronze, Copper, and Aluminum. At EA Craftworks, we also have equipment for bending round and square bar stock.

Beyond Metal

Our fantastic millwork and materials partners can provide countertops, live edge wood, hand rails and a variety of other material components outside of wood and metal.

Your Local Metal Experts

Whether in a commercial, residential, or exterior setting, EA Craftworks has created projects to enhance the environment they were placed in. We work in a variety of metals and finishes and can help guide you in choosing the best materials and finishes for the project you are working on. Decorative and durable for a countertop, an elegant iron stair railing, or a unique sculpture or signage. We have done all of that and more and would love to help you with your unique vision.