Tube Rolling and Forming

Shaping Steel With Precision

Steel tubing is a staple in many architectural and artistic projects—but shaping it into smooth, consistent curves is no easy task. Unlike solid bar stock, tubing is hollow, which makes it more prone to distortion when force is applied. Without the right tools and techniques, bends can result in crimping, kinking, or flattening—compromising both the look and structural integrity of the material.

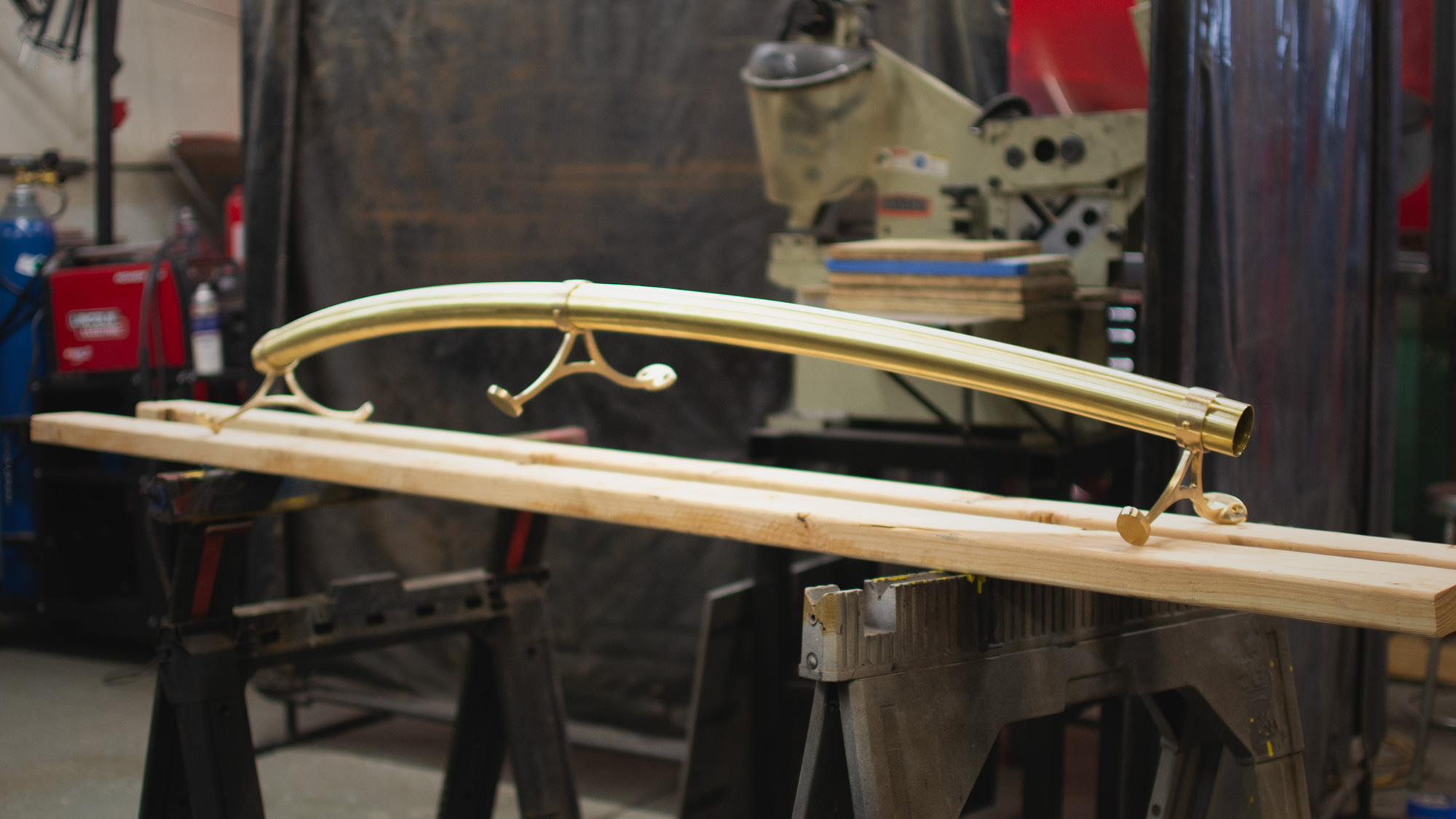

At EA Craftworks, we specialize in controlled tube forming, delivering clean, reliable curves with precision and repeatability. Whether we’re working with round, square, or rectangular tubing, our goal is always the same: maintain the integrity of the profile while achieving the desired shape.

Why Tube Forming Requires Specialized Techniques

Because tubing lacks internal reinforcement, it reacts differently than solid metal when subjected to pressure. As a result, traditional bending methods often fail to provide the necessary control to maintain the tubing’s shape and dimensions. This is especially true for larger radii or more complex curves.

That’s where tube rolling comes in. Tube rolling gradually forms the tubing using consistent pressure, rather than abrupt force. The process allows for greater control and reduces the risk of unwanted deformation.

How Tube Rolling Works

At EA Craftworks, we use a tube roller—a specialized machine equipped with a set of adjustable dies designed to match the tubing profile. The tubing is passed through the dies multiple times, with incremental pressure applied each pass to slowly and evenly roll the material into the desired arc or curve.

This method is ideal for achieving graceful, uniform shapes while maintaining the clean lines and structural consistency that our clients expect. By selecting the appropriate dies and carefully calibrating the rolling pressure, we can work with a wide range of tubing types and sizes to meet both functional and aesthetic goals.

Applications of Tube Rolling

Tube rolling opens up a world of design possibilities. We regularly use this process to fabricate components for:

- Custom Furniture Frames – Clean curves and modern lines for tables, chairs, and shelving.

- Fire Pit Enclosures & Outdoor Features – Rounded forms that bring warmth and style to exterior spaces.

- Sculptural Elements – Organic shapes for artistic and public installations.

- Architectural Accents – Curved railings, signage frames, and structural supports.

Whether your project calls for subtle arcs or dramatic circular forms, our team can bring your ideas to life with precision-rolled tubing.

Bring Your Curved Concepts to Life

If your next project involves curved surfaces, rolled frames, or tubing in any form, EA Craftworks is ready to collaborate. Our experienced team can help you explore possibilities, advise on fabrication best practices, and deliver rolled metalwork that fits your design vision.

Let’s talk about your next project—get in touch and let us help shape what’s next.