Metal finishing processes include grinding, sanding, and de-buring. Metal can be finished many ways for design and aesthetic purposes, and is usually finished with a clear coat to protect the material. Examples include:

- Raw steel rusting

- Etching raw steel, aluminum, brass, bronze, and copper

No clear coat is need as stainless steel will not rust. These finishes can also be touched up after years of use to become "new" again.

Polishing stainless steel to a mirror finish is a time consuming, detail oriented process. This is one of our high-end applications.

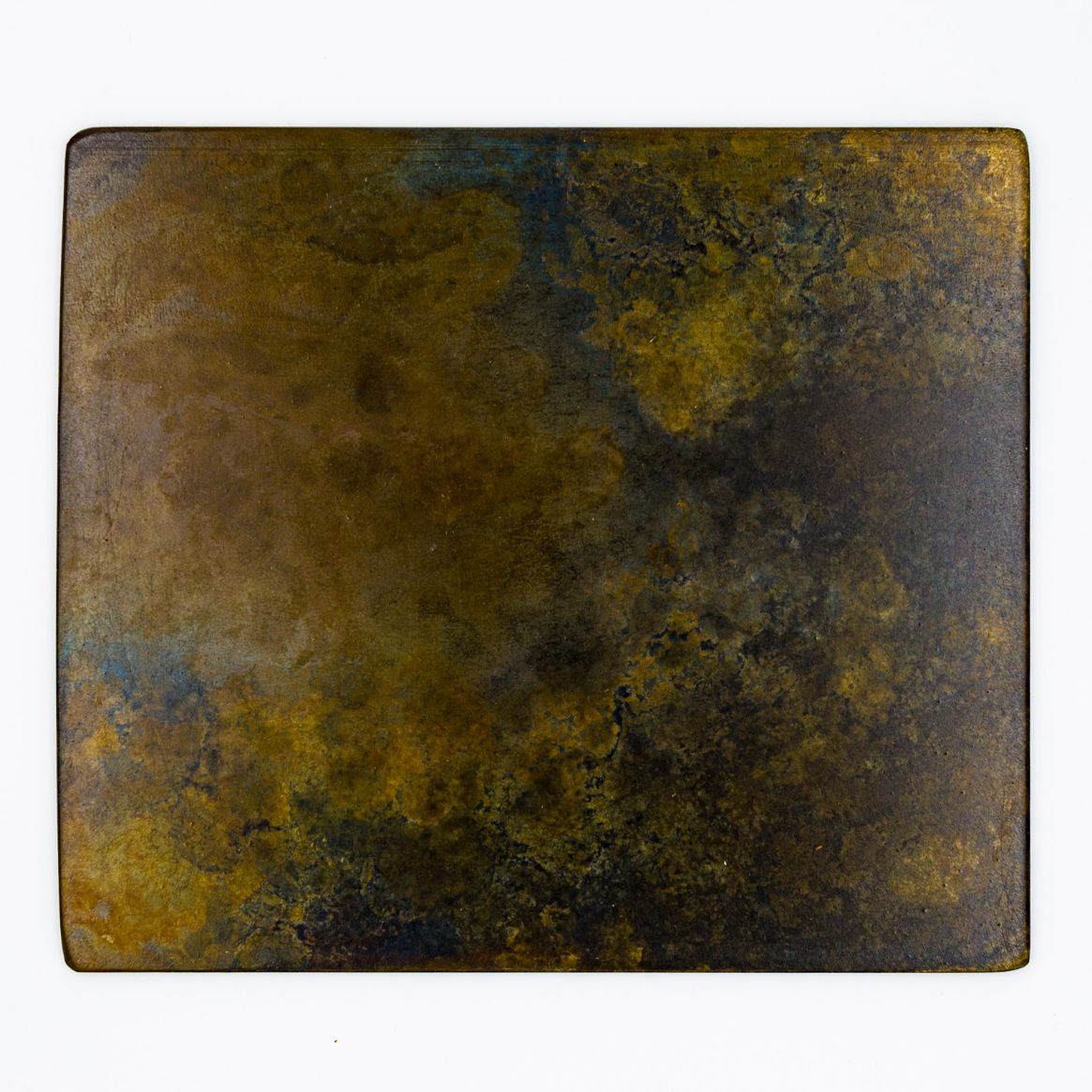

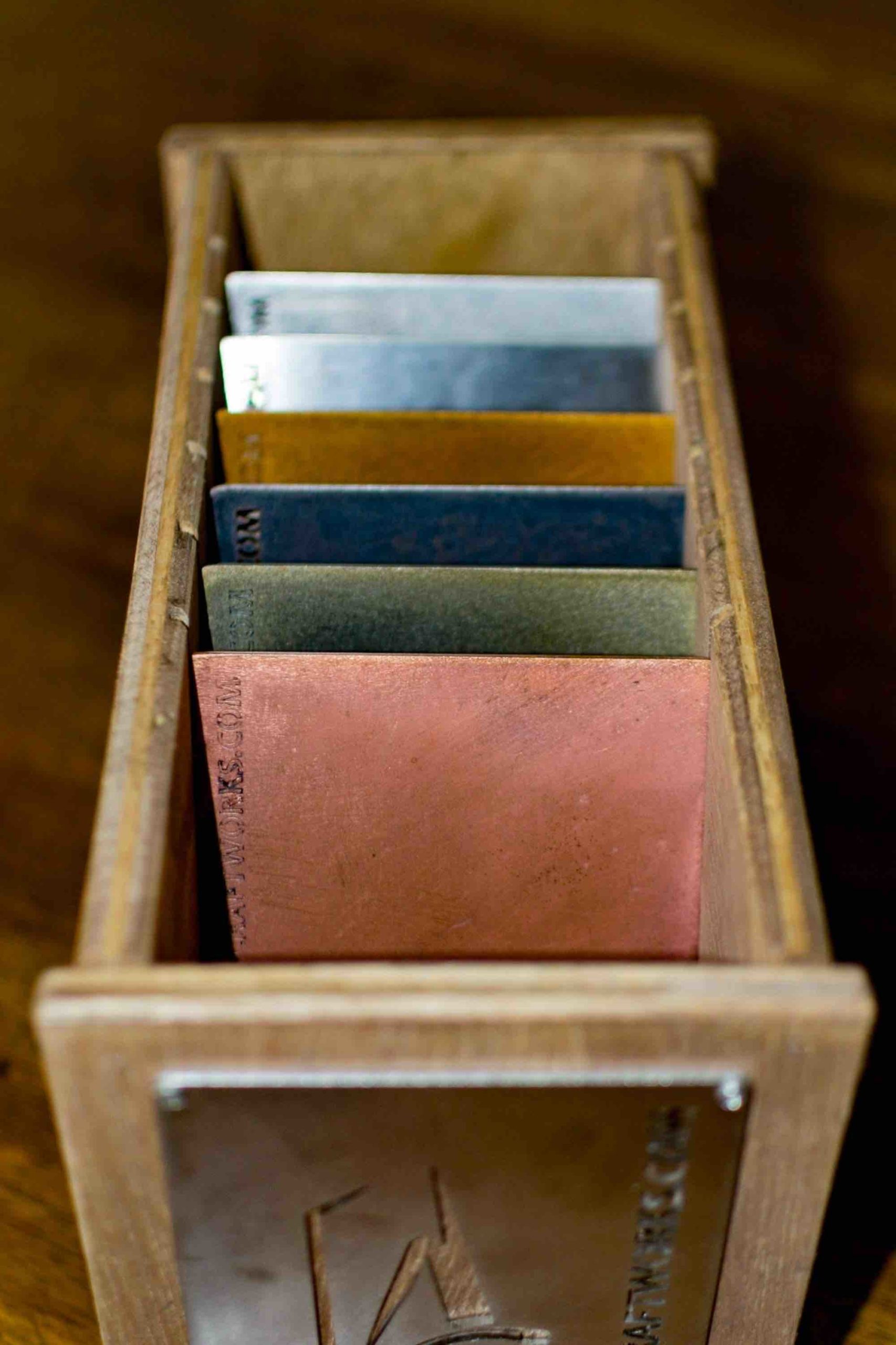

Custom patina on metal involves applying a coating, usually an acid based product, to raw steel, stainless steel, aluminum, bronze, copper, or brass. The surface of the material will change via a chemical reaction to the product applied. Many different patinas can be achieved through various products and applications.

Different patinas will chemical react differently with different base metals.

Etching is done for design or aesthetic purposes. We etch raw steel, aluminum, brass, bronze, and copper.

Need Help with a Custom Project?

Contact us to get started.