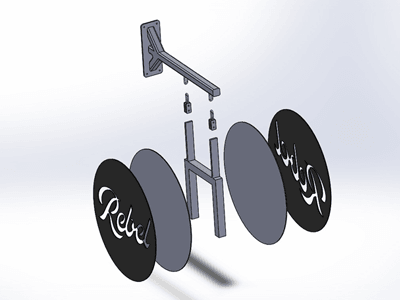

EA combines our deep experience in 3D Modeling (SolidWorks, Rhino, Keyshot) with innovative and precise fabrication techniques to help customers with many prototyping needs. We review customer designs and ideas and are often able to provide design tweaks and suggestions that maximize utility while increasing production efficiencies or provide increased aesthetic value and charm.

A sampling of some of our custom fabrication projects and capabilities include metal marketing tags, cabinets and furniture, furniture components, lighting systems, hand rails, industrial safety equipment, and decorative metal items such as wall screens, signage, sculpture, and a variety of architectural items.

See more on our Custom Products page.

Fabrication tools are the tools that we use to turn raw material into products and components for you.

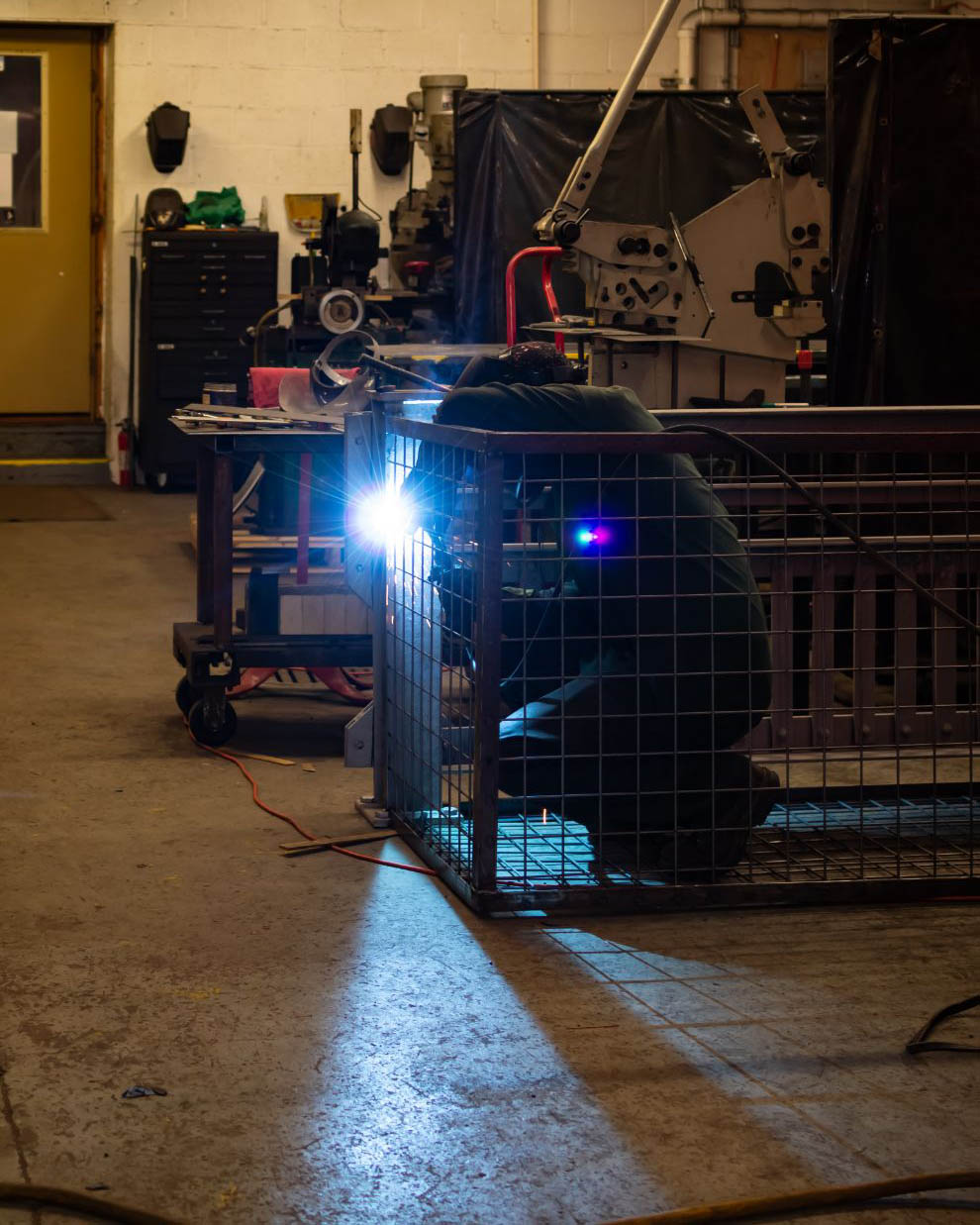

Welding is a process used in fabrication. Welding uses machinery to join metal subcomponents into products.

EA is experienced in spray-line tooling needs. We will work with you to develop custom tooling solutions that provide superior coverage with minimal overspray.

- MIG (metal inert gas) - fast efficient way to join metal pieces together. It melts wire much like a hot glue gun.

- TIG (tungsten inert gas) - a more precise and cleaner method of welding than MIG. It creates a weld that doesn’t require much cleanup and can be left as a decorative feature. You probably have seen “the look” on finer metal furniture and architecture.

- Oxy-fuel welding (oxyacetylene welding, brazing) - flame welding using a controlled flame from a welding torch. This is the oldest of the welding ways. These days, we most commonly use it for brass work. Brass is a softer metal that requires more craft in working with it, and sometimes old school is the way to go.

- Spot welding (electric resistance welding) - is an efficient and quick way to join sheet metal together. This method melts metal together at the joining spot.