Blog

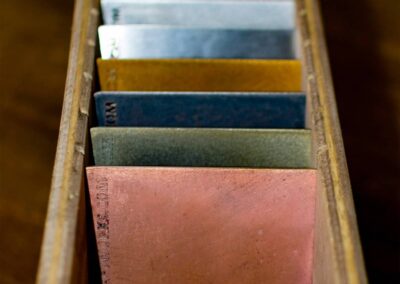

The Art of Metal Finishing

Unveil the magic of metal finishing. From the beauty of patina to the strength of powder coating, see how EA Craftworks crafts perfection.

Turning Visions into Reality with EA’s Expertise

EA bridges dream and reality. Dive into our design journey from idea refinement to expert fabrication. Your vision, our craftsmanship.

Metal Cladding and Paneling: A Fusion of Function and Aesthetics in Interior Design

Metal cladding and paneling are versatile design elements that can be employed in a multitude of ways within a space.

Custom Metal Railing Systems

Custom Metal Railings offer safety, style, and elegance to any space. EA Craftworks can provide tailor-made solutions to meet your needs.

Computer-Aided Design (CAD) – Architectural Elements

Computer-Aided Design (CAD) is a vital part of creating beautiful, functional, and efficiently made architectural products for our clients.

Metal Patina Intro

Many patina processes use multiple types of acids that can be layered to great effect, or use heat to enhance the specific look by opening the ‘pores’ of the metal.

MIG & TIG Welding Intro

The most common welding processes are MIG and TIG. While MIG is like a “hot glue gun” for metal, TIG is a slower process that requires a skilled hand.